Our proven execution methodology guides our process for implementing solutions in a safe, cost-effective, and timely manner, meeting and exceeding project objectives.

Our expertise in the food industry allows us to design and construct processes for Raw Material Handling, Cooking, Cooling, Mixing, Emulsification, Homogenization, Cleaning in Place (CIP), and Customized Systems.

We design and automate systems for the Safe Transfer of Liquid Food and Cleaning Solutions through valve clusters for mixing.

Learn moreWe design and build CIP (Cleaning in Place) and SIP (Integrated Cleaning and Sterilization) systems to eliminate all residues and deposits and eliminate microorganisms.

Learn moreWe pay special attention to the complete interior surface: stainless steel adheres to the highest DIN standard, and the complete interior welding is done according to the ASME standard.

Learn more

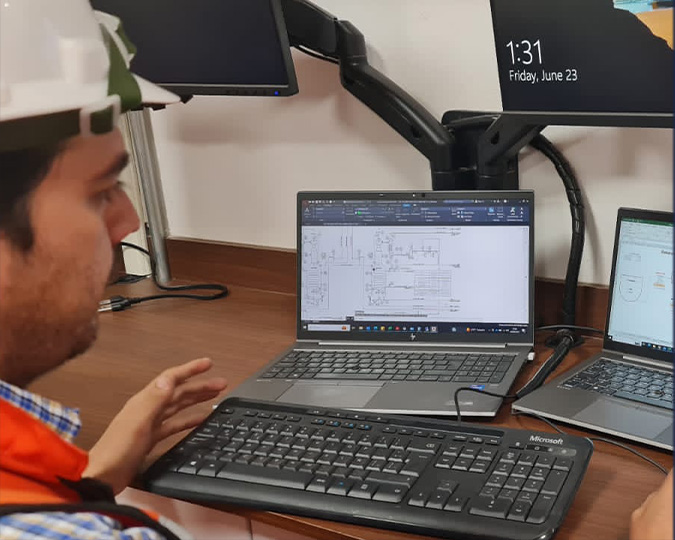

Our engineers design and plan from the master plan of a project, including the interaction of all projects.

Learn moreMaintaining product quality is a key concern for the food industry. We are well aware that batch system automation solutions must meet special requirements.

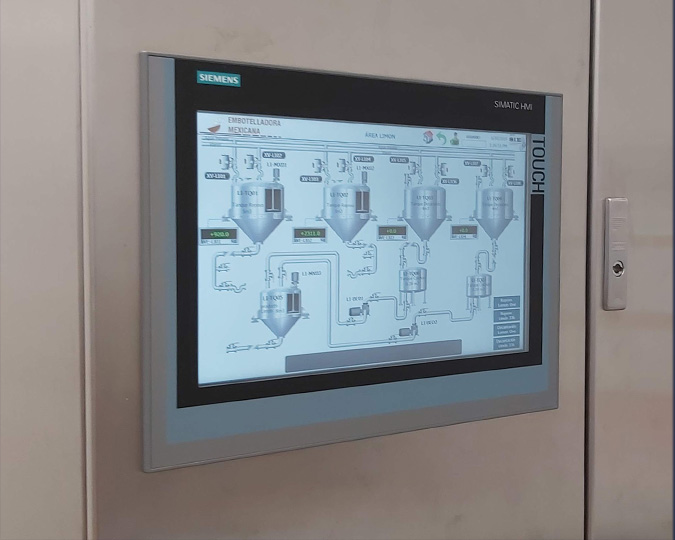

Learn moreIntegrated systems with Programmable Logic Controllers (PLC) and Human-Machine Interfaces (HMI) allow efficient and secure control of each production process.

Learn moreManufacturing facilities and machines increasingly face the challenge of these issues, demanding a centralized, efficient, and industry-based global solution for automated production plants.

Learn more

Manufacturing facilities and machines increasingly face the challenge of these issues, demanding a centralized, efficient, and industry-based global solution for automated production plants.

Learn more